Training

FoodPlus offers a range of short courses to meet the needs of the food manufacturing industry.

The training courses developed by FoodPlus are structured to maximise learning through a balanced blend of theory and hands-on practical activities. Each program is designed to suit participants from a wide range of backgrounds, experience levels, and technical knowledge.

All courses can be delivered on-site at your facility, with select programs also offered at a central venue in Scoresby, Victoria.

Programs range from one to three days, with pricing determined by course length, participant numbers, and location. All learning materials are included, and every attendee receives a Certificate of Participation.

If you’re interested in any of the courses listed below and would like to discuss your training needs, please get in touch via the ‘Enquire Now’ section or the contact details below.

Training Courses

Cheese Courses

-

A one-day short course for those who want to better understand the science and technology of cheesemaking.

This course explores the science and technology of cheese, starting from the raw milk, ingredients (cultures, rennet, salt), processing and through to the maturation. An in depth look at the key factors that impact cheese quality is undertaken to equip participants with the knowledge to understand the ‘how’ and ‘why’ of what is happening in the cheesemaking process. The course includes a ‘hands on’ cheesemaking practical exercise.

LEARNING OUTCOMES

Understand the science and technology of cheese ingredients, manufacture and maturation.

Gain insights into the practical aspects of cheesemaking.

Demonstrate problem solving skills for cheese quality defects and improvements.

COURSE OUTLINE

Milk Chemistry & Microbiology

Raw Milk Quality

Milk Standardisation & Pasteurisation

Cultures & Rennet

Cheese Make

Cheese Maturation

Cheese Defects

Cheese Making Exercise

WHO SHOULD ATTEND

New cheesemakers.

More experienced cheesemakers who want to understand the how and why of cheesemaking.

Technical, procurement and Sales staff wanting to gain better insights into the cheesemaking process and products.

-

A one-day short course for those who want to learn more about the functionality of Mozzarella cheese, especially the factors that impact it’s performance in the pizza cook test.

LEARNING OUTCOMES

Understand the Science and Technology of Mozzarella manufacture.

Recognise the Mozzarella Cook Testing parameters.

Investigate the functional performance of Mozzarella on Pizzas.

Identify the Manufacturing factors that affect Mozzarella functionality

COURSE OUTLINE

The Science and Technology of Mozzarella Cheese.

Mozzarella manufacture - milk, cultures, rennet, salting, processing.

Pizza Cook Test descriptors and parameters.

Key factors that impact Mozzarella functionality of pizzas.

WHO SHOULD ATTEND

Cheesemakers who want a better understanding of the performance of their cheese in the pizza cook test and manufacturing parameters that can improve it’s quality.

Technical and R&D staff who want to develop, improve and optimise the quality of their Mozzarella cheese.

Sales / marketing personnel who want to better understand Mozzarella functionality and the pizza cook test parameters.

-

Cheesemaking is a mixture of knowledge, skill and experience. In this 3 ½-day cheesemaking workshop we will equip participants to gain a better understanding of the cheesemaking process as well as acquire practical skills through hands-on cheesemaking of different cheese types in small scale bench top vats.

COURSE OUTLINE

Cheesemaking theory - ingredients, cultures, processes, equipment, maturation, grading.

Hands-on cheesemaking of the following cheeses.

Cheddar

Mozzarella

Feta

Parmesan

Ricotta

(Please note other cheese types can be included as per client requirements).

Basic Cheese Grading practical.

LEARNING OUTCOMES

Participants will acquire skills in making 5 different types of cheeses.

Gain knowledge of the basic science and technology of cheesemaking.

Extend their understanding of the ingredients, processes and equipment used in cheesemaking.

Gain insights into how the cheesemaking process can impact cheese quality, functionality and maturation.

Gain insights into the different salting processes - dry and bine.

WHO SHOULD ATTEND

New, inexperienced, and experienced cheesemakers who want to gain a better understanding of the ingredients, processes, and control of cheesemaking and cheese quality.

Non-production staff who want to gain important insights into the cheese-making process to better enhance their roles.

-

The understanding and application of cheese yield knowledge and principles has the potential to save companies significant amounts of money and optimise the available milk resources.

In this one-day course we examine the milk chemistry, ingredients and cheese making process and unpack cheese yield formulas and calculations. A large focus of the course is to explore the factors that impact cheese yield and how they can be implemented at your manufacturing site.

LEARNING OUTCOMES

Cheese yield formulas and calculations.

Interpreting cheese yield measurements.

Milk chemistry and the significance of the milk components on cheese yield.

Impact of raw milk quality.

Protein standardisation and heat treatment.

Cheese Vat design.

Cheese make implications - Setting / Cutting / Draining / Milling / Salting.

Sampling & testing.

COURSE OUTLINE

Understand formulas and calculations used to measure cheese yield accurately.

Apply knowledge of the impact of milk components, ingredients and cheese make on maximising cheese yield.

Insights into the critical make parameters that impact cheese yield and the key sampling and testing requirements.

Group discussion and exercise.

-

This two-day short course explores how cheese is technically graded, covering cheese sensory science, cheese attributes and defects, and the different grading systems used.

LEARNING OUTCOMES

Acquire knowledge in cheese sensory science and the cheese grading systems.

Be equipped to carry out cheese grading to skillfully identify key appearance, texture and flavour attributes and defects in different cheeses.

Gain insights into cheese maturation including flavour development and textural changes.

COURSE OUTLINE

Cheese Sensory science.

Cheese types.

Cheese sensory attributes – appearance / texture / flavour.

Cheese typical attributes.

Grade scoring – Defect and Attribute grading systems.

Cheesemaking & maturation.

The grading environment.

Manufacturing parameters that impact defects and grade score.

Cheese grading exercises.

Cheese Science and Technology

Cheese Grading

-

This two-day short course explores Sensory Science and the Sensory Attributes & Defects of the main dairy product groups.

LEARNING OUTCOMES

Equip participants in understanding the science and attributes of a range of dairy products.

Participants will gain practical experience in evaluating different dairy products to identify key sensory attributes and product defects.

Participants will acquire insights into linking product defects to manufacturing parameters.

COURSE OUTLINE

Product groups covered:

Milk & cream – fresh, flavoured, ESL, UHT.

Cultured dairy - yoghurts, fermented drinks.

Cheeses - main groups.

Butter, spreads, milk & whey powders.

·Exploring sensory science.

·Understanding Product sensory attributes.

·Factors that impact sensory judgments.

·Setting up and running sensory panels.

·The course includes a significant amount of product evaluation and group exercises.

WHO SHOULD ATTEND

Those wanting to understand more about the sensory properties of dairy products.

New to the dairy industry.

Technical, Quality, and Production personnel.

Staff wanting to set up and run a site-based sensory evaluation / panel.

Technologist looking to develop new products.

-

A one-day short course that dives into the chemistry, microbiology, and processing of fresh milk and creams.

LEARNING OUTCOMES

Understand the science and technology of fresh milk and fresh cream products.

Insights into how fresh milk and cream are processed and packed.

Demonstrate knowledge and skills of linking milk and cream science to quality defects and improvements, including shelf life.

COURSE OUTLINE

Raw milk and cream quality.

Standardisation, homogenisation, and membrane filtration of milk.

Pasteurisation.

Product Packing.

Product shelf life.

Milk and cream sensory.

Quality defects and problem solving.

-

This 1 ½ day short course explores the Science and Technology of Yoghurts and Fermented drinks.

This course is applicable to dairy and non-dairy yoghurts and fermented products.

LEARNING OUTCOMES

Participants will gain a deeper understanding of the science and technology for yoghurts and fermented drinks.

Understanding of the ingredients, fermentation, and processing technologies involved in producing quality fermented yoghurt products.

Insights into the quality and sensory attributes of yoghurts and fermented dairy products.

COURSE OUTLINE

Science and technology of fermented dairy type products

Milk chemistry and microbiology.

Starter cultures – types, how they work, bacteriophage management.

The fermentation process – ingredients, process conditions, equipment.

Quality and food safety requirements.

Sensory attributes and defects.

Product shelf life.

Practical hands-on yoghurt making exercise.

-

A one-day short course for dairy factory operators involved or planning to be involved in the receival and processing of raw milk and cream.

LEARNING OUTCOMES

Demonstrate an understanding of raw milk and cream receival, storage and testing procedures:

Knowledge and skills in the processing of raw milk and cream.

Understanding of storage and processing equipment cleaning procedures.

Best practice food safety requirements.

COURSE OUTLINE

Raw milk and cream quality.

Raw milk & cream receival procedures and food safety requirements.

Raw milk & cream sampling and testing – antibiotics, sensory, titratable acidity, pH.

Raw milk & cream processing – basic milk chemistry, seperation, membrane filtration, standardisation.

Tanker bay and processing equipment cleaning – CIP and manual cleaning.

-

A one-day introductory course to the dairy processing industry. The course overviews the dairy industry with particular focus on the products manufactured with reference to the basics of the processing techniques, product functionality, sensory, and packaging.

LEARNING OUTCOMES

Equip participants in understanding the different dairy products including the basic dairy science, functionality and sensory attributes.

Participants will be skilled with the knowledge to:

Understand how each dairy product group is manufactured from raw milk to finished goods.

The basic sensory and functionality attributes of each product group.

Gain insights into the end use of the product – retail, foodservice, ingredient.

COURSE OUTLINE

An overview of the dairy industry and farm milk production basics.

Exploring the main product groups – milks & cream, cheese, butter, yoghurt, ice cream, milk & whey powders.

Overview of the manufacturing processes for each product group.

Assessing the sensory attributes of each product group.

Assessing the functionality attributes of different products groups – includes hands on practical activities.

Evaluating the packaging types used for different products.

WHO SHOULD ATTEND

New to the dairy industry.

Staff from Management, Sales & Marketing, Procurement, Finance, People & Culture, Engineering, Quality, Graduates, as well as Technologists looking to develop new products.

-

This one-day short course explores the science and sensory attributes & defects of Ice Cream and related products.

LEARNING OUTCOMES

Equip participants in understanding the science and processing of ice cream and related products.

Participants will gain practical experience in evaluating ice cream to identify key sensory attributes and product defects.

Participants will acquire insights into linking product defects to manufacturing parameters.

COURSE OUTLINE

Sensory science theory.

Ice cream manufacture including ingredient, processing, packaging.

Understanding Product sensory attributes and defects.

The course includes a significant amount of product evaluation and group exercises.

WHO SHOULD ATTEND

Those wanting to understand more about the sensory properties of ice cream and related products.

New to ice cream manufacture, distribution or sales.

Technical, Quality, and Production personnel.

-

A one-day introductory short course that explores the science, technology, and applications of milk and protein powders.

LEARNING OUTCOMES

Awareness of the regulatory standards and specifications for the different powder products.

Understand the science and technology of milk and protein powders and the manufacturing process.

Describe the functionality of the different powders and how this impacts their end use.

Gain insights into the factors that impact product quality and shelf life.

COURSE OUTLINE

Product range, regulatory standards, and specifications.

Manufacturing processes.

Product quality and shelf life.

Product sensory.

Quality defects and problem-solving activities.

-

A one-day introductory short course that explores the science, technology, and applications of cream and dairy fat products.

LEARNING OUTCOMES

Awareness of the regulatory standards and specifications for the dairy fat-related products.

Understand the science and technology of cream and dairy fat products, and the related manufacturing processes.

Describe the functionality of the different products and how this impacts their end use.

Gain insights into the factors that impact product quality and shelf life.

COURSE OUTLINE

Product range, regulatory standards, and specifications.

Fresh and long-life cream.

Butter and butter blends.

AMF & Ghee.

The different manufacturing processes.

Product quality and shelf life.

Product sensory.

Quality defects and problem-solving activities.

Raw Milk & Cream Receival and Processing

Introduction to Dairy Products and Processes

-

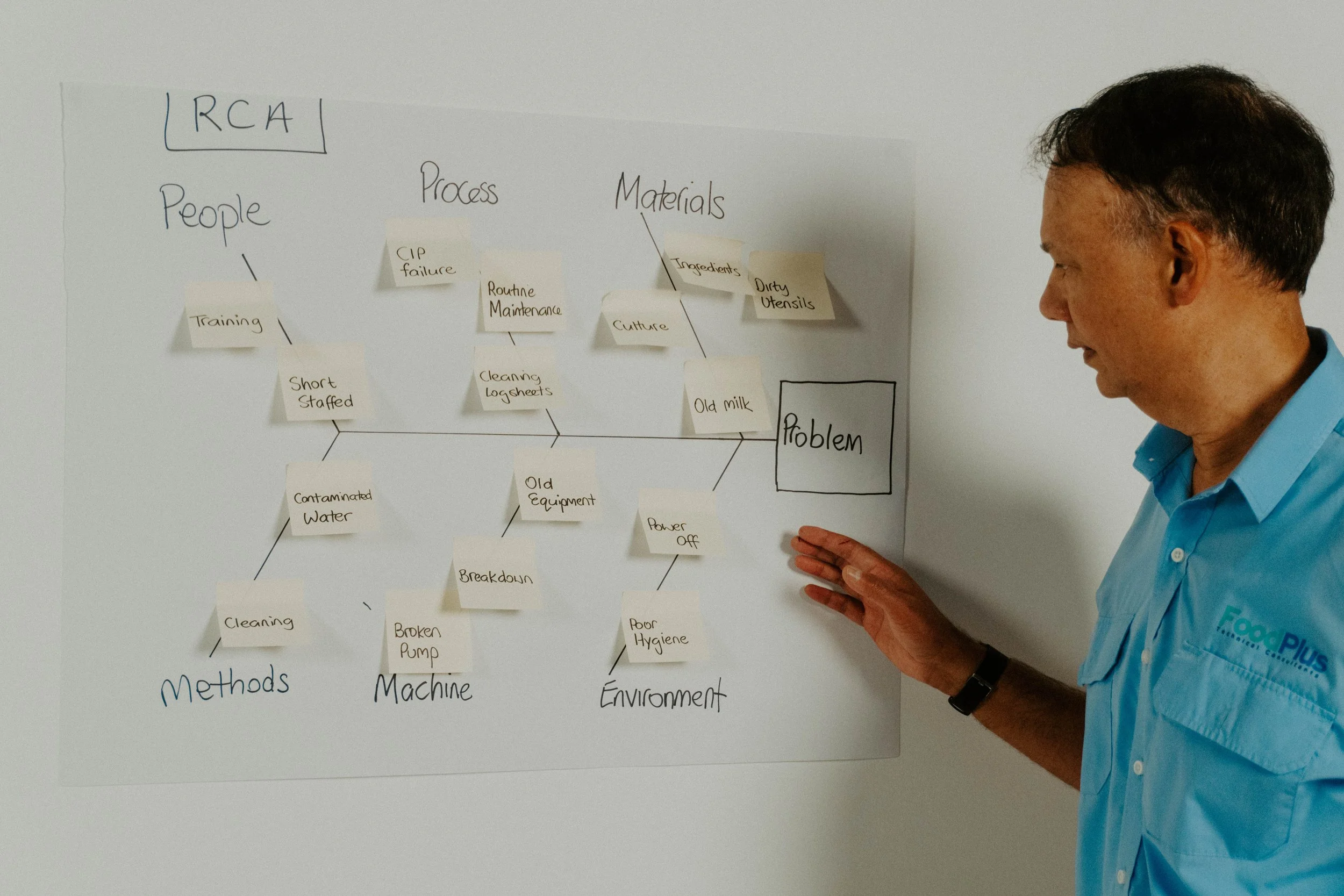

Root Cause Analysis (RCA) is a team based systematic approach to identify the root causes of difficult problems and provide appropriate solutions. In this one-day short course we equip participants with the knowledge, tools and processes to carry out effective root causes analysis. The course incorporates theory, tools and templates, as well as practical exercises to enforce the learning techniques.

LEARNING OUTCOMES

Participants will learn the skills to effectively define a problem and identify the probable root causes to resolve the issue.

Understand the different tools available to systematically investigate problems.

Help build site capability through sound problem solving leadership and team building activities.

COURSE OUTLINE

The importance of properly defining the problem.

Explore the LEAN tools used to carry out an effective RCA.

Leading an RCA team.

Team based practical activities for problem-solving difficult product and process issues to identify root cause.

WHO SHOULD ATTEND

Effective RCA problem solving work best with a wide range of staff from different departments inputing into the process. Additional to Production, Quality and Maintenance staff, participants from other non-technical departments can bring valuable insights into the RCA process.

-

This two-day course is designed for Quality, Production, Maintenance and Technical staff who are looking for a deeper understanding of food microbiology and the sourcing of pathogenic and food spoilage organisms in product and in the manufacturing process. The course reviews the various tools and methods that can be used and incorporates hands-on practical activities for participants to reinforce their microbiological learning.

LEARNING OUTCOMES

Participants will gain deeper insights into the key microorganisms that impact food safety and spoilage.

A greater understanding of manufacturing and cleaning processes, and how they impact the contamination of the product.

Demonstrate problem-solving skills to help identify, source, and manage microbiological contamination of product.

COURSE OUTLINE

Detailed review of the key microorganisms that impact food safety and spoilage.

Manufacturing processes and how they impact the contamination of the product.

Explore problem-solving tools to help identify, source, and manage microbiological contamination of product.

Product and environmental Sampling Programs.

CIP and Manual Cleaning.

Learning activities include theory, group discussion, case studies, and problem-solving activities.

-

GMP is key to the production of safe food products. We have designed this course for line operators to gain better knowledge and understanding of the GMP principles, and more importantly, as to why these are so important.

This one-day course explores all the key aspects of GMP as well as food safety hazards, cleaning, and cross-contamination risks.

LEARNING OUTCOMES

Participants will have reinforced knowledge and skills in Good Manufacturing Practices.

Better understanding of pathogenic and food spoilage microorganisms.

Insights into food safety risks associated with allergens, chemicals, and foreign matter.

Demonstrate awareness of food safety hazards and cross-contamination of products.

COURSE OUTLINE

Site and universal GMP requirements.

Basic microbiology - pathogenic and food spoilage organisms.

Other Food Safety Hazards – chemical, allergen, physical (foreign matter).

Cross-contamination risks.

Cleaning procedures - CIP & Manual Cleaning.

Learning activities – theory, case studies, group discussion practical activities.

-

GMP is key to the production of safe food products. We have designed this course for line operators to gain better knowledge and understanding of the GMP principles, and more importantly, as to why these are so important. The course explores all the key aspects of GMP as well as food safety hazards, cleaning, and cross-contamination risks.

LEARNING OUTCOMES

Participants will have reinforced knowledge and skills in Good Manufacturing Practices.

Better understanding of pathogenic and food spoilage microorganisms.

Insights into food safety risks associated with allergens, chemicals, and foreign matter.

Demonstrate awareness of food safety hazards and cross-contamination of products.

COURSE OUTLINE

Site and universal GMP requirements.

Basic microbiology - pathogenic and food spoilage organisms.

Other Food Safety Hazards – chemical, allergen, physical (foreign matter).

Cross-contamination risks.

Cleaning procedures - CIP & Manual Cleaning.

Learning activities – theory, case studies, group discussion practical activities.

-

Inadequate cleaning is one of the main causes of contamination of food products.

This two-day short course explores CIP systems and manual cleaning to help food manufacturing personnel understand the fundamentals, workings and processes involved in effective and efficient cleaning of food processing equipment and the surrounding environment.

LEARNING OUTCOMES

Demonstrate a deeper understanding of CIP systems and manual cleaning, and how they work in the cleaning of food processing equipment.

Describe the different elements of CIP systems and how to investigate cleaning failures when they arise.

Be equipped with learnings and tools to better optimise the CIP system for effectiveness and efficiency.

Understand the tools and processes associated with CIP validation and verification activities.

COURSE OUTLINE

CIP fundamentals – design, equipment, chemicals, flow rates, times, temperatures.

Introduction to process microbiology.

CIP running and optimisation for effectiveness and efficiency.

Manual cleaning.

Validation and verification activities.

Preventative and corrective actions.

The course will include theory as well as case studies, practical and group problem-solving activities.

WHO SHOULD ATTEND

Production Operators, Leading Hands / Supervisors, Managers.

Quality, Maintenance, Continuous Improvement, Product Development staff.

Cheese Making

Mozzarella Functionality

Other Dairy Courses

Dairy Product Sensory

Fresh Milk & Cream Science & Technology

Food Safety & Problem Solving

Cheese Yield

Fermented Dairy

Root Cause Analysis (RCA)

Microbiological Problem Solving & Tracebacks

Food Safety, Quality & Cross Contamination.